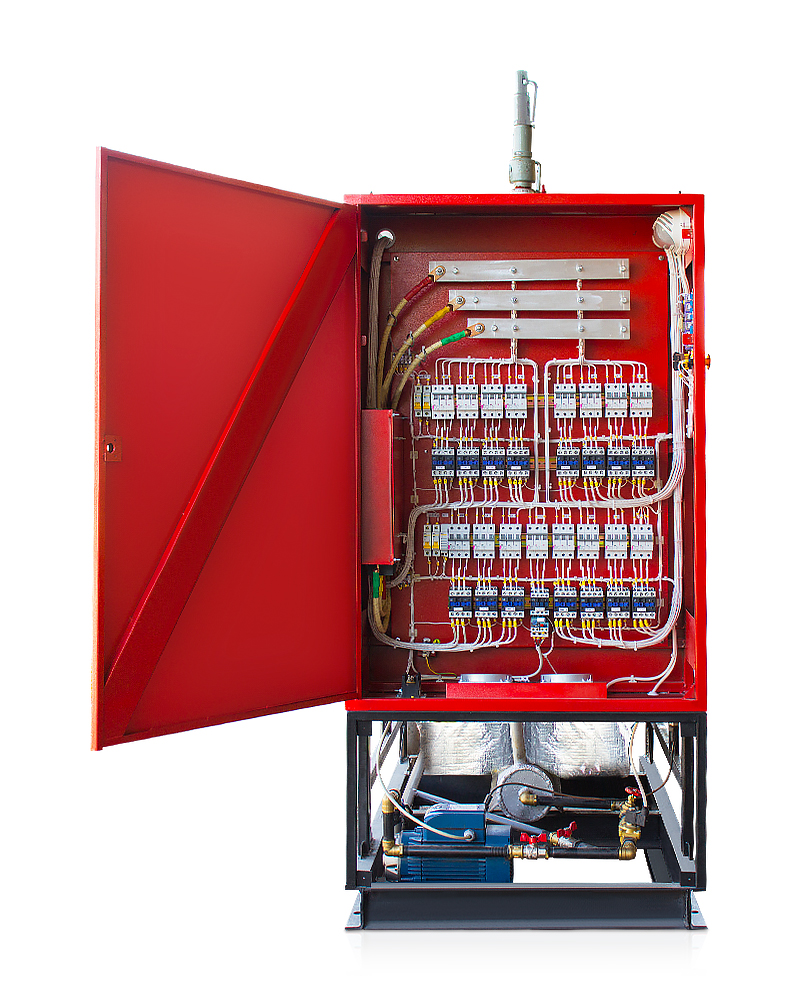

Electric steam generators

An industrial steam generator is a specialized unit, the main purpose of which is the rapid and controlled production of steam, which can be used as a technological agent in a variety of industries or as a source of thermal energy. The key advantage of the device when used in a specific production is the ability to adapt to its needs. Thereby obtaining high levels of process automation and minimizing resource losses.

The principle of operation of a steam generator

Steam-generating equipment performs its function by transforming electrical energy into thermal energy. The process begins when prepared water is fed into a heating chamber with electrical elements (heating elements) installed for this purpose. The formation of superheated or saturated steam occurs after the water reaches the boiling point and is then used depending on production needs.

Benefits of purchasing steam equipment

- In high-tech industries, the use of such an installation is of particular priority, because the steam generator has sensitive control, which allows you to set both the temperature regime and the pressure of the steam itself as accurately as possible. This ensures the stability of technological processes.

- The industrial electric steam generator has 0% of harmful emissions, such as soot, carbon dioxide and nitrogen oxide, which are emitted by devices running on fuel oil, gas and coal. That is, the equipment presented on our website does not violate the established environmental standards and allows employees to work safely in production facilities, because the absence of flammable materials minimizes the likelihood of ignition.

- Using the installation, resource distribution becomes more rational, since the steam generator avoids overspending on electricity due to automated systems that produce only the required amount of steam.

- The absence of fuel valves, burners and other complex mechanical components reduces the percentage of breakdowns, which accordingly reduces maintenance costs.

Selection recommendations

The choice of industrial equipment directly affects the efficiency of the entire production, so when buying, we recommend paying attention to these parameters:

- Steam volume and pressure. It is important to calculate the number of kg of steam per hour, as well as the pressure that meets the needs of your business. For example: up to 40 kg/h of steam can satisfy the demand of a small food enterprise, for the chemical and textile industries this figure can be 100 kg/h or more.

- An industrial steam generator should be purchased taking into account the wiring capabilities relative to the power of the installation. With a power of 60-480 kW, it is necessary to connect exclusively to a three-phase network (380 V).